Pipe Type: ERW Pipe, ERW Steel Pipe, Electric Resistance Welded Pipe, HFW Steel Pipe, EFW Steel Pipe

Application: For Low Pressure Fluid Transmission, Machinery Manufacturing

Specification: OD: 21.3mm ~ 660mm

WT: 1mm ~ 17.5mm

LENGTH: 0.5mtr ~ 22mtr (5.8/6/11.8/12 meters, SRL, DRL)

Standard & Grade: API 5L PSL1/PSL2 Gr.A,Gr.B,X42,X46,X52,X56,X60,X65,X70

ASTM A53, ASTM A500, JIS G3466, ASTM A252, ASTM A178, AN/NZS 1163, AN/NZS 1074, EN10219-1, EN10217-1

End: Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Surface: Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc Galvanized/Anti-corrosive Coating

Packing: Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

For details, delivery time and prices, please mail us

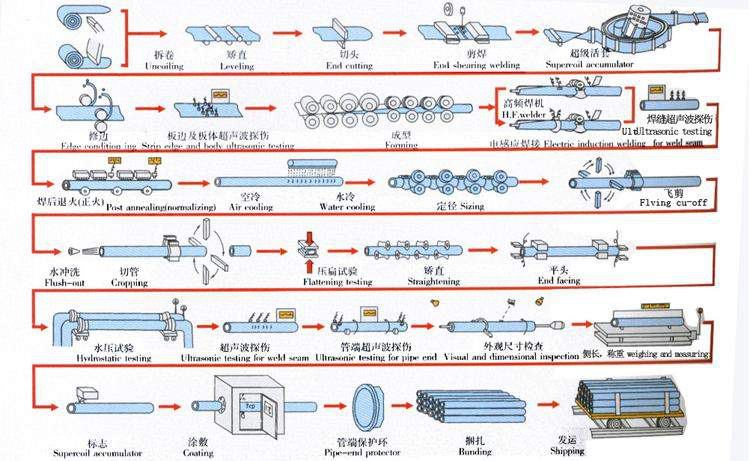

Production Process for ERW Steel Pipe:

1.Uncoiling --- 2. Leveling --- 3. End cutting --- 4. End shearing welding --- 5. Supercoil accumulator --- 6. Edge cutting --- 7. Ultrasonic detection --- 8. Forming --- 9. Electric induction welding --- 10. Ultrasonic detection for weld seam --- 11. Medium frequency heat treatment --- 12. Air cooling --- 13. Water cooling --- 14. Sizing --- 15. Flying cutting --- 16. Flush-out --- 17. Cropping --- 18. Flattening testing --- 19. Straightening --- 20. End facing and bevelling --- 21. Hydrodynamic testing --- 22. Ultrasonic detection for weld seam --- 23. Ultrasonic detection for pipe end --- 24. Visual and dimensions inspection --- 25.Weighting and measuring --- 26. Marking --- 27. Coating --- 28. Pipe-end protection --- 29. Bending --- 30. Shipping

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tolerance of ERW steel pipe

| Standard | Grade | Out Diameter Tolerance | Wall Thickness Tolerance |

| ASTM A53 | A | +/-1.0% | +/- 12.5% |

| B | +/- 1.0% | +/- 12.5% |

Chemical Analysis & Mechanical Properties of ERW steel pipe

| Standard | Grade | Chemical Analysis(%) | Mechanical Properties(min)(Mpa) | ||||

| C | Mn | P | S | Tensile Strength | Yield Strength | ||

| ASTM A53 | A | 0.25 | 0.95 | 0.05 | 0.045 | 330 | 205 |

| B | 0.30 | 1.20 | 0.05 | 0.045 | 415 | 240 | |

Product Advantages of ERW Steel Pipe

Advantages of erw steel pipe are following below:

A) High dimensional accuracy. ERW steel pipe diameter and wall thickness than the seamless steel pipe deviation is much smaller, because the strip rolling and pipe forming easy to control, so high dimensional accuracy.

B) Good mechanical properties. As the ERW steel pipe with easy control of rolling, with the welding technology and on-line heat treatment technology, the performance of the weld can be controlled, so straight seam welded steel pipe elongation than seamless steel pipe 8% -10% higher, which Is because the straight seam electric-welded pipe carbon content of less than 12% lower than the seamless tube.

C) ERW steel pipe with high concentricity, uniform wall thickness. Weld after heat treatment, microstructure uniform, with a strong ability to collapse collapse.

D) As the extension of the steel is good, straight seam sewing machine sister pipe flattening test is better than seamless.

E) The impact toughness of ERW steel pipe is higher than that of seamless steel pipe.

F) Longitudinal resistance welded pipe is not welded into the dissimilar metals, but also undergo a rigorous on-line heat treatment, so the basic performance of the weld and material properties.