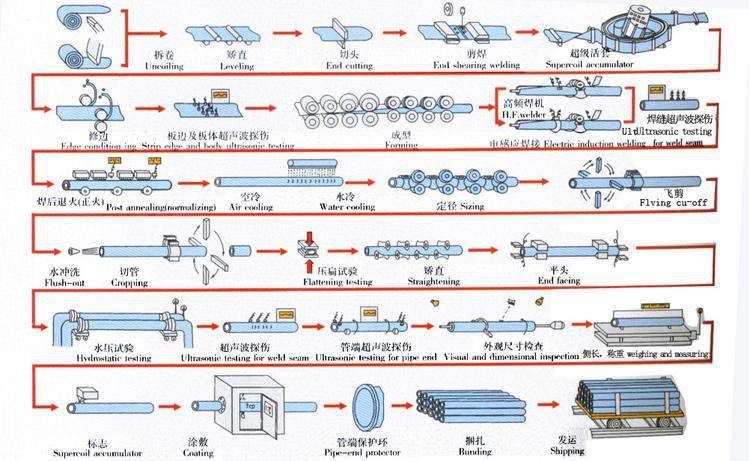

Production Process of Fire Fighting Steel Pipe

1.Uncoiling --- 2. Leveling --- 3. End cutting --- 4. End shearing welding --- 5. Supercoil accumulator --- 6. Edge cutting --- 7. Ultrasonic detection --- 8. Forming --- 9. Electric induction welding --- 10. Ultrasonic detection for weld seam ---11. Medium frequency heat treatment --- 12. Air cooling --- 13. Water cooling --- 14. Sizing --- 15. Flying cutting --- 16. Flush-out --- 17. Cropping --- 18. Flattening testing --- 19. Straightening --- 20. End facing and bevelling --- 21. Hydrodynamic testing --- 22. Ultrasonic detection for weld seam --- 23. Ultrasonic detection for pipe end --- 24. Visual and dimensions inspection --- 25.Weighting and measuring --- 26. Marking --- 27. Coating --- 28. Pipe-end protection ---29. Bending --- 30. Shipping

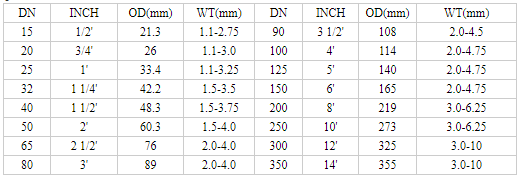

Specification of Fire Fighting Steel Pipe

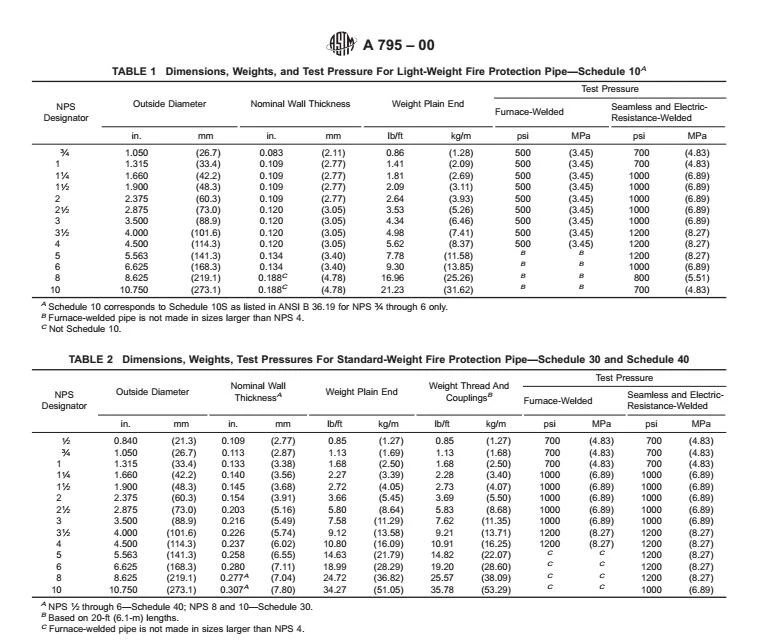

Technical Data of Fire Fighting Steel Pipe

Prodcut Advantages of Fire Fighting Steel Pipe

1. Fire Fighting Steel Pipe has strong flame retardant ability. Under the combustion test of alcohol blowtorch, the coating has no spontaneous combustion and does not fall off.

2. Good mechanical properties and high strength of fire fighting steel tubes.It has strong bearing capacity, impact resistance and bending resistance.

3. Fire Fighting Steel Pipe corrosion resistance is strong.It has good resistance to high expansion foam extinguishing agent corrosion and protein foam extinguishing agent corrosion.

4. Fire Fighting Steel Pipe water resistance is small, energy saving.The inner wall of the pipeline is smooth and fine, which greatly reduces the energy consumption of transportation.